3D Printing in Construction: A Game-Changer in the Industry

The construction industry is undergoing a significant shift toward technological advancement and 3D printing is one of the groundbreaking technologies leading the way. 3D printed homes, which once seemed like science fiction and futuristic concepts have now been materialized into reality. In this blog, we’ll explore how 3D printing works, its benefits, challenges, and future potential.

What is Industry 4.0?

Historically, the world has known several industrial revolutions. At the end of the 18th century, mechanized systems powered by water and streams emerged leading to the development of large-scale factories. At the end of the 19th century, the world witnessed the introduction of electrical energy and assembly lines increasing the mass production in the factories. The third industrial revolution started at the end of the 20th century when computers and automation technologies emerged and when the internet and mobile devices were invented. Now, we are living in the era of the fourth revolution. Smart machines and interconnected systems are being created due to the remarkable reliance on emerging technologies such as artificial intelligence and the development of 3D printing technology.

What is 3D Printing?

3D printing, also known as additive manufacturing (AM), consists of deposing materials layer by layer to create three-dimensional objects. For this purpose, a 3D model is created, appropriate materials are chosen, and a 3D printer is used.

This technology has been employed in a wide range of industries, including aerospace, automotive, medical, energy, and food using a variety of additive manufacturing methods. Different printer types, different printing techniques, and different printing materials have been developed throughout the years.

The most common 3D printing techniques used in concrete construction are Extrusion-based and Powder-based (D-shape) techniques. On the other hand, different types of printers have been manufactured and used in construction such as Fixed Robotic Arms, Gantry, Cable Robots, and Mobile Robot Systems.

How Does 3D Printing Work?

The 3D printing process starts by creating a digital model of the building or the building components using design software. Then, the model file is transmitted into a slicing software to become readable by the 3D printer. Following the exact designed geometry, the model is then printed by the 3D printer layer by layer to have finally a 3D printed object without the use of any formwork or human intervention.

For the extrusion method, which is typically used in construction, conventional mixes are prepared including cementitious materials, water, aggregates, and admixtures. Then, concrete is pumped through hoses from the mixer and extruded as filament through the printer nozzle to create the printed element.

The different building components can be directly printed on-site or printed off-site and then transported to the construction site for assembly.

What are the Advantages of 3D Printing?

Compared to conventional construction methods, 3D printing technology presents several advantages:

- Design flexibility: If you can imagine it, you can print it! The 3D printing technique pushed the boundary in design. It offers flexibility in printing complex shapes and architectural details that are usually impossible or time-consuming if executed with conventional construction methods.

- Construction speed: Houses have been built in less than 24 hours! The 3D printing technique allows completing projects in a very short time making it a very effective technique to be adopted for emergency houses and low-income housing projects.

- Cost saving and sustainability: Less time, less waste, and less labor cost! The 3D printing technique allows printing with precision without requiring formwork and extensive labor costs, leading to more affordable and sustainable construction.

What are the Limitations of 3D Printing?

Despite being a promising technology, the wide application of 3D printing in construction is still facing several challenges that need to be addressed:

- Materials Limitations: To avoid nozzle clogging, the maximum particle size of the materials (aggregates and fibers) used in 3D printing should be relatively small.

- Reinforcement incorporation: Embedding traditional reinforcement within 3D printed structures poses remarkable challenges and the automation process of placing the reinforcement while printing necessitates an advanced robotics system. Thus, without proper and adequate reinforcement, 3D-printed structures may fail to meet the load-bearing requirements for specific applications.

- Lack of regulations: The lack of building codes, standards, or governmental rules related to 3D printing in most countries slows down the adoption of the technology to avoid facing legal or safety issues.

- Restricted building size: The printer size and current printing technology present challenges to scale up from small-scale projects (such as homes and offices) to large-scale projects (such as bridges and skyscrapers). Thus, the technology and equipment need to evolve to meet the demands of large-scale construction.

What is the Future of 3D Printing?

This emerging technology is getting considerable attention in different parts of the world including the MEA, Africa, Europe, USA, and Mexico. Dubai, for example, is aiming to have 25% of its buildings based on 3D printing technologies by 2030 and it has already created a law to regulate 3D printing in construction. In addition to the construction of offices and houses, the technology was used to build indoor and outdoor furniture, manholes, decorative elements, shell walls, and wind turbines.

By investing in research and development, the aforementioned challenges related to 3D printing are expected to be overcome. The advancements in technology and equipment and the development of printers capable of simultaneously laying concrete and reinforcement will lead to wider adoption of 3D printing even in large-scale projects and the creation of regulatory frameworks. On the other hand, the incorporation of innovative and eco-friendly materials will make the 3D printing process more sustainable and versatile.

But will the planet Earth be the limit? Apparently, it will not. NASA is evaluating the construction on the moon and Mars by adopting the 3D printing technique using Lunar and Martian soil. This technique is considered a promising technology to overcome the challenges of transporting construction and equipment materials to space.

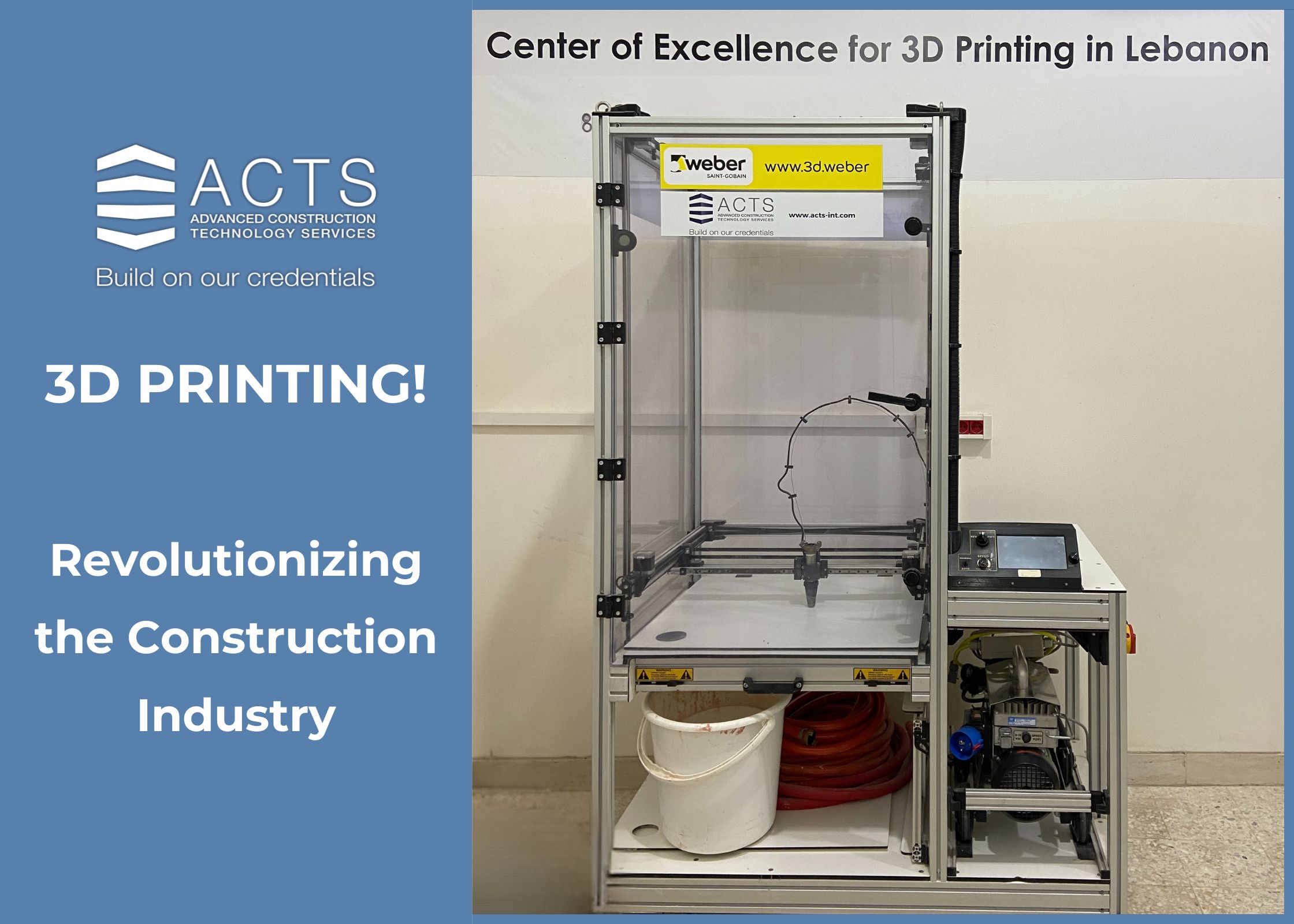

ACTS Initiative: Center of Excellence for 3D Printing

ACTS believes that is not only important to embrace innovation individually but it is also essential to collaborate with industrial stakeholders and invest in education to empower future generations and motivate them to become drivers of innovation, progress, and positive change in society.

In alignment with this vision, ACTS entered into a partnership agreement with Weber Saint-Gobain to create the Center of Excellence for 3D concrete printing as a platform for learning and growth for future generations. The Center of Excellence serves as a hub for the Research and Development of 3D printing and its applications in construction in Lebanon and the MENA Region. By linking industrial and academic sectors, the center will address advanced strategic and oriented research while aligning the research with the industry and business needs. Moreover, the center will provide students with experience and training in 3D printing to introduce them to the latest technologies in the construction field and prepare them for related careers.

For this purpose, a 3D concrete printer is now available at ACTS laboratory in Beirut branch in Lebanon. It is manufactured by Weber Saint-Gobain and it is a gantry-type printer. The printer can print mortar with a maximum particle size of 2 mm. The printed element can reach 50 cm in diameter and 1 m in height with a maximum mass of 200 kg.

Conclusions

3D printing technology is not just a futuristic concept. It is a promising technology providing numerous advantages such as an increase in geometric flexibility, fast building time, cost efficiency, and sustainability. Although some challenges persist, mainly related to material and building size limitations, lack of regulations, and the placement of proper reinforcement, 3D printing technology has the potential to reshape the construction industry and tackle global housing demands and infrastructure growth.

Article written by Dr. Faten Abi Farraj, Ph.D. Civil Engineering.

Head of R&D and Technical Services at ACTS.

Share on