Non-Destructive Testing (NDT) - The Silent Guardian of Our Infrastructure

The world of engineering is witnessing a paradigm shift towards smarter, safer, and more sustainable practices, and Non-Destructive Testing (NDT) is the hero leading this charge. Just as medical imaging allows doctors to see inside the human body without surgery, NDT allows engineers to see inside steel, concrete, and pipelines without altering them. In this blog, we’ll explore the world of NDT, from its ancient roots to its futuristic "4.0" evolution.

1 - The First Line of Defense: Visual Inspection (VI)

-

The Power of the Naked Eye

Before any complex machinery is used, the most powerful tool is often the human eye. Visual Inspection is the oldest, most basic, and most widely used NDT method. It serves as the prerequisite for almost all other NDT methods; if a part is visibly damaged, there is no need to waste time or money on advanced scanning.

-

Reaching the Unreachable: Industrial Endoscopy & RVI

What happens when the defect is hidden inside a complex engine, a turbine blade, or a narrow pipe where the human eye cannot reach? This is where Industrial Endoscopy and Remote Visual Inspection (RVI) come into play.

The Internal Eye: Similar to medical endoscopy, industrial videoscopes use flexible, lighted tubes with high-definition cameras at the tip. These probes can steer through the intricate twisting passages of a turbine or a heat exchanger, allowing engineers to inspect internal components without the costly and time-consuming process of disassembly.

Drones & Robots: RVI takes visual inspection further by deploying unmanned systems. Robotic crawlers can travel hundreds of meters inside sewer lines or pipelines to inspect welds and blockages. Meanwhile, drones (UAVs) equipped with high-zoom cameras and thermal sensors soar to inspect wind turbine blades, bridges, and high-voltage towers.

2 - NDT: Seeing the Unseen

Non-Destructive Testing (NDT) is a wide group of analysis techniques used in the science and technology industry to evaluate the properties of a material, component, or system without causing damage. Unlike destructive testing, where a sample is broken to test its strength, NDT allows the part to still be used after inspection. It is an effective way for Quality Assurance (QA) and Quality Control (QC) in critical industries like aerospace, construction, and oil & gas.

Different materials and defects require different ways to see them; therefore, the NDT conducted on concrete differs from that used for steel, as presented in the following sections.

3 - Conventional NDT Techniques in Concrete

Concrete is a complex mixture, requiring specialized acoustic and electromagnetic waves to assess its integrity, thickness, and strength.

-

Ground Penetrating Radar (GPR)

GPR is the industry standard for locating hidden elements inside concrete, such as rebar, post-tension cables, and voids. It sends high-frequency electromagnetic waves into the structure, which reflect off objects with different electrical properties. These reflections create an image of the subsurface, allowing engineers to drill or cut safely without hitting critical reinforcement.

-

Ultrasonic Pulse Velocity (UPV)

UPV checks the uniformity and quality of concrete by measuring how fast an ultrasonic pulse travels through it. Since sound travels faster through dense material, a high velocity indicates good quality, while slower speeds alert inspectors to internal cracks, honeycombing, or voids that could compromise strength.

-

Impact Echo (IE)

Impact Echo is designed to measure plate thickness and detect delamination (separation of layers). It uses a mechanical tap to generate stress waves that reflect off the back wall or internal flaws. By analyzing the frequency of these returning echoes, engineers can precisely determine the member's depth or locate hidden defects.

-

Spectral Analysis of Surface Waves (SASW)

SASW is the preferred technique for determining the stiffness profile of concrete layers. A hammer impact generates surface waves of various frequencies, which are measured by receivers to analyze how fast they travel at different depths. This data helps build a stiffness profile, revealing the quality of the concrete layers beneath the surface and the depth of defects.

-

Schmidt Hammer (Rebound Hammer)

The Schmidt Hammer provides a quick, on-site estimation of surface hardness. A spring-loaded mass strikes the concrete, and the distance of its rebound is measured. A higher rebound number indicates a harder and stronger surface, making it an efficient tool for rapidly screening large areas for weakness.

4 - Conventional NDT Techniques in Metallurgy

The most conventional techniques in metallurgy are presented in the following sections.

-

Liquid Penetrant Testing (PT)

Used for non-porous materials to find surface-breaking cracks, a liquid dye is applied to the surface and drawn into cracks by capillary action. Excess dye is removed, and a "developer" is applied to pull the trapped dye back out, creating a visible indication of the defects.

-

Magnetic Particle Testing (MPT)

The MPT is used for ferromagnetic materials (like iron and steel). The tested part is magnetized, and if there is a crack, the magnetic field leaks out at the defect. Then, iron particles are applied and are attracted to this "leak", making the crack visible.

-

Radiographic Testing (RT)

X-rays or Gamma rays are passed through the material onto film or a digital sensor. Thicker or denser areas absorb more radiation while cracks or voids absorb less, appearing as darker spots on the image.

-

Ultrasonic Testing (UT)

A transducer sends high-frequency sound waves into the material. These waves reflect off the back wall or any internal defect (like a crack or void). The time it takes for the echo to return helps locate and size the defect.

-

Eddy Current Testing (ECT)

Used for conductive materials to detect surface and near-surface defects. A coil carrying current creates a magnetic field, inducing "eddy currents" in the tested material. Therefore, the defects disrupt these currents, changing the impedance, which is detected by the instrument.

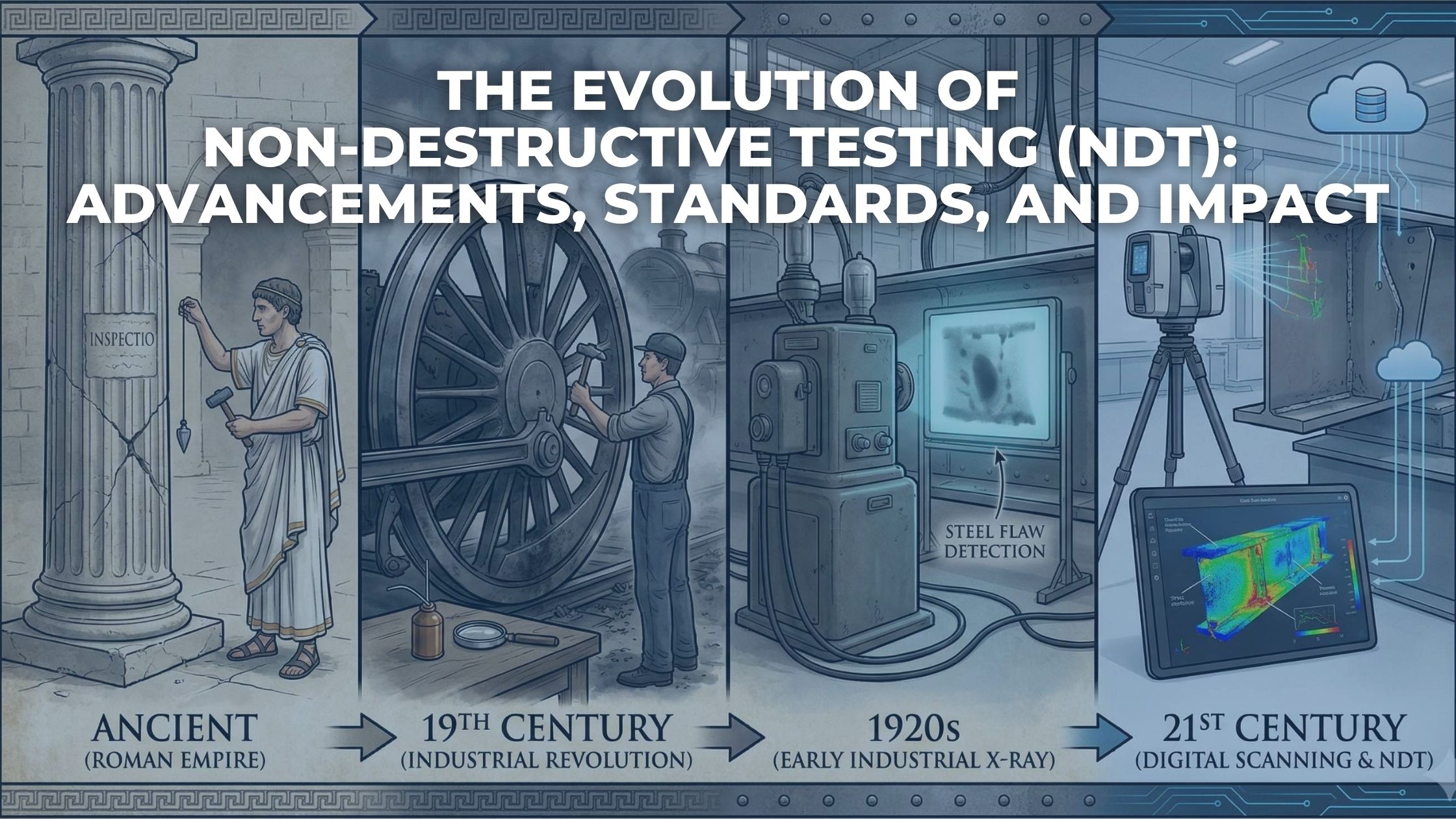

5 - The Evolution of NDT: From Ancient Eyes to AI Minds

The story of Non-Destructive Testing is the story of industrial progress itself. As humanity moved from building stone temples to manufacturing smart cities, the inspection methods evolved from simple sensory checks to autonomous digital systems, evolving from NDT 1.0 to 4.0.

NDT 1.0: The Era of Senses (Ancient Times - 19th Century)

In the beginning, inspection relied entirely on the human senses (looking, listening, and tapping).

Ancient Origins: The roots of NDT trace back to the Romans, who reportedly used a mixture of flour and oil to detect cracks in marble slabs, an early precursor to Liquid Penetrant Testing.

The Industrial Awakening: As steam engines and railways emerged, the "Oil and Whiting" method became common for checking railway parts, relying on visual contrast to find cracks. This was NDT in its rawest form: relying on the operator's eye and experience.

NDT 2.0: The Era of Tools & Analog (Late 19th Century - Mid 20th Century)

The second revolution was driven by the discovery of physics-based tools that allowed the engineers to see what the eye could not.

The Scientific Breakthrough: In 1895, Wilhelm Röntgen discovered X-rays, allowing engineers to see inside solid objects for the first time.

Wartime Innovation: World War II accelerated the need for reliability. Techniques like Ultrasonic Testing (UT) and Magnetic Particle Testing (MPT) were standardized to ensure the safety of military aircraft and ships. This era moved inspection from subjective guessing to objective measurement.

NDT 3.0: The Era of Digital (Late 20th Century)

Just as computers transformed offices, they transformed inspection.

Going Digital: This era saw the transition from analog screens and chemical film to digital sensors and software. Computers allowed for data storage, clearer imaging, and easier reporting.

Enhanced Precision: Instruments became smaller, faster, and more accurate, but they still largely required a human operator to move the probe and interpret the data.

NDT 4.0: The Era of Intelligence (21st Century & Beyond)

Today, we are living in the era of the fourth revolution, where inspection meets the Internet of Things (IoT) and Artificial Intelligence (AI).

NDT 4.0 involves smart sensors that continuously monitor structures (Structural Health Monitoring) without human intervention.

Autonomous Inspection: Drones equipped with thermographic cameras or scanners can inspect dangerous heights or pipelines autonomously.

Predictive Power: By using Digital Twins and AI, we don't just find defects; we predict them before they happen, moving from reactive repairs to proactive maintenance.

6 - 24/7 Guardians: Structural Health Monitoring (SHM)

While traditional NDT involves periodic check-ups (like a doctor's visit), Structural Health Monitoring (SHM) is like wearing a fitness tracker 24/7.

SHM involves embedding smart sensors (fiber optic, acoustic, or wireless) directly into structures like bridges, dams, and skyscrapers during or after construction.

These sensors provide real-time data on stress, vibration, and crack growth. Instead of guessing when repairs are needed, engineers receive instant alerts on their dashboard if the structure's "health" declines, preventing sudden collapses.

7 - The Benefits of NDT

Compared to destructive methods or purely visual guesswork, NDT offers immense value:

Safety and Accident Prevention: It detects hidden flaws before they cause catastrophic failures.

Cost Efficiency: It prevents downtime. For example, testing a pipeline while it is still in operation is far cheaper than shutting it down.

Quality Control: It ensures that every single manufactured part meets the standards, not just a random sample.

Sustainability: NDT reduces the carbon footprint by extending the life of existing structures through targeted repairs and preventing the waste associated with demolition or material production.

8 - The Blind Spots of NDT

Despite its advantages, NDT has some constraints:

Material Specificity: Not all methods work on all materials (e.g., some methods only work on magnetic metals).

Operator Dependence: Many methods require highly skilled and certified technicians to interpret the results accurately. A mistake in interpretation can affect the testing outcomes.

Access: Some methods require access to both sides of a material or specific surface preparation (cleaning or removing paint).

9 - ACTS: Pioneering NDT and SHM Excellence

Non-Destructive Testing and Structural Health Monitoring is the bridge between safety and efficiency. It allows building higher, flying faster, and exploring deeper without the fear of sudden failure. From the simple visual checks of the past to the AI-driven inspections of NDT 4.0, accompanied by SHM of the structures, this technology continues to evolve, so the future of infrastructure is not just being built; it is being carefully watched over, ensuring a safer and more sustainable construction.

Equipped with accredited laboratories and certified inspectors who offer a full suite of NDT and SHM services, Advanced Construction Technology Services (ACTS) provides solutions that verify the integrity of the most critical assets in the construction and industrial fields, ensuring that every inspection meets the highest global benchmarks.